Liquefied Natural Gas (LNG)

Introduction

Transportation of natural gas by means other than pipelines requires that the gas be liquefied to conserve space and make transportation economically viable. When natural gas is cooled to about -260 degrees Fahrenheit it is liquid and has a volume about 600 times less than in the gaseous state. In liquid form it is suitable for both transportation and storage.

The Process

The process: Turning natural gas into a liquid compresses it to a volume of about 1/600 of its gaseous state, making it possible to transport and store fuel from remote sites where pipeline construction is impractical.

- The gas must be cooled to -260 degrees Fahrenheit (-161 degrees Celsius), a temperature which must be maintained throughout its storage and transport by ship or truck.

- When a specially-designed LNG carrier arrives at a receiving terminal, its cargo is unloaded, re-gasified and sent through a pipeline to where it's needed.

- LNG is clear, colorless, odorless, non-corrosive, and non-toxic.

A Brief History

A brief history. Technologies to liquefy natural gas, store it and ship it in specially designed vessels to any part of the world that has the infrastructure to receive it have been in use for many years. The first liquefication plant in the U.S. came on line in 1941, but regular exports of American LNG began in 1969 going from Alaska to Japan.

In the early 2000's, American natural gas supplies began to dwindle, causing prices to rise. As a result the U.S. has supplemented its domestic supplies with reasonably-priced gas imported through pipelines from Canada. Over the past decade America has also increased its capacity to import LNG. (Trinidad and Tobago provided the U.S. with 31% of its LNG in 2011.)

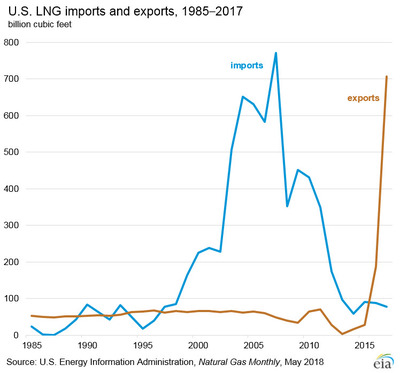

Most recently, the U.S. has become a net exporter of LNG. This is due to an increase in U.S. natural gas production and expansion of the exporting capacity of U.S. terminals. The above chart shows the history of LNG imports and exports from 1985-2017.

Shale Gas

Shale gas changes the whole American natural gas picture. Instead of adding import terminals, the country will likely need more LNG export terminals, as the possibility of producing enough gas for U.S. consumption and exporting LNG to foreign markets becomes a reality. Presently, the single export terminal - in Kenai, Alaska - ships LNG to the West Coast. Three other mainland import terminals have been authorized to "re-export" LNG. If U.S. gas becomes competitive in international markets, more LNG export terminals may be developed.

LNG Terminal Development

Commercial development for an LNG terminal begins with a confirmed sale, or GSA (gas sales agreement) to a buyer willing to contract to rigorous terms and pricing structures for 20 to 25 years. These are arranged to ensure the long-term economic viability of a terminal. To date the largest importers of LNG are Japan, Korea, Spain and Taiwan. The largest exporters are Qatar, Malaysia, Indonesia and Australia.

Safety Concerns

Safety concerns:

- Natural gas, whether as a vapor or liquid, is a fossil fuel, but its emissions of carbon dioxide are the lowest in the fossil fuel family. Production, shipping and re-gasification of LNG add more CO2 to the atmosphere than conventional gas, but over the distances LNG is transported, its CO2 emissions are lower than piped gas.

- LNG as a liquid can cause damage due to its extremely cold temperatures. It must be handled and contained with great care.

- In case of an LNG spill, a vapor cloud will form. If its gas concentration reaches 5 to 15 percent in air, a spark could ignite an explosion and intensely hot fire.

- Terrorist attack of an LNG processing plant or tanker in an urban area.

Regulation

Regulators:

- Internationally, the U.N.'s Maritime Organization, the IMO, oversees LNG tanker safety.

- U.S. ports' federally-mandated rules are enforced by the Coast Guard.

- The Department of Transportation issues and enforces safety standards for LNG facilities on land.

- The Federal Energy Regulatory Commission oversees the process, issuing the strictest standards if necessary.